Ceramics

Backed with more than 20 years of experience in the ceramic industries, Alzar can provide ceramic manufacturers with a wide range of products and services. We can be your one stop shop for all your raw material needs:

Minerals such as Kaolin, Bentonite, Feldspar, etc.

Different types of custom-designed deflocculants for various applications such as Body, Glaze, Sanitaryware, Porcelain, Specialty Ceramics, Oxide Ceramic, Alumina, Concrete, Cement and Refractories, etc.

Binders for increasing MOR and dry and green strength

Binders for Glazes

Binders and Plasticizers for Refractories

Different types of custom-designed CMC (Carboxy Methyl Cellulose) for Glaze

Additives for screen printing

Fixing agents

Thickening and Binding agent (glue) for ceramic glazes

Non-Foaming & Foaming Surfactants

Preserving agent for ceramic glazes and ceramic mixes

Different Coatings and Glazes for Ceramic and Porcelain Tiles

Founded in 1988, Colores Olucha produces high-quality ceramic pigments, digital printing inks and raw materials specially designed for top-range industries.

We offer a personalized service for our customers because we

understand that our customers are the most important part of

our company.

Colores Olucha S.L is a company involved in a constant

effort in research and development for producing

quality products which satisfy the needs and demands of the

international market.

We also guarantee the control of the production process and

the quality of the finished products.

Machineries

Schäffer designs and manufactures high quality loaders for use in agriculture, landscape gardening, municipal services, building work, and construction. Schäffer's loaders are especially designed for ease of maneuverability to navigate tight areas.

Yard, wheel and telescopic loaders from Germany are available which provide bundled power, compact machine design and highest reliability.

SCHÄFFER LOADERS FOR THE AGRICULTURAL BUSINESS

In many agricultural enterprises our loaders become “part of the family”. They are indispensible machines used all day long with many applications thanks to a large choice of tools. They many tasks much easier and contribute to the increased efficiency of the enterprise.

SCHÄFFER LOADERS FOR THE CONSTRUCTION SECTOR

Our yellow machines were designed specifically for the needs of construction, landscaping, municipal services and industry. Despite their compact dimensions, these

dynamic powerhouses are able to transport enormous loads. Their typically stable Schäffer design of swinging fork, lifting cylinder and supports is of specific importance with these machines.

BvL Maschinenfabrik has been in business for more than 150 years. Family-owned from the beginning, BvL Maschinenfabrik has always relied on great managing directors, who have played a key role in the company's history.

BvL is the leader in providing customized agriculture machineries, including mixer wagons, unloading technology and the DairyFeeder.

Bernard van Lengerich has been a household name for customized solutions since 1860. We will provide you with the products you need to optimize your profit and keep your animals as healthy as possible:

Feeding equipment

Unloading technology

Bedding technology

Biogas equipment

System technology

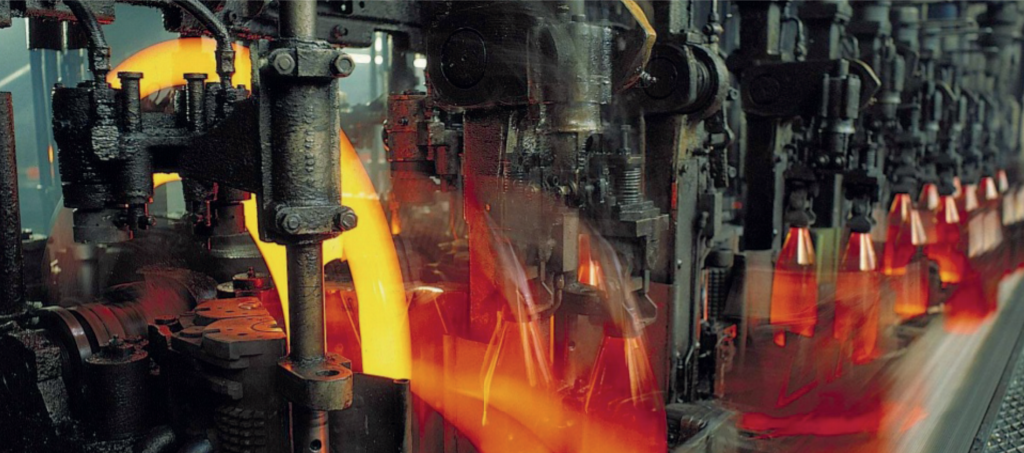

Glass

- Futronic GmbH

- Refmon Monolithics Co. Ltd.

- UAS Messtechnik GmbH

- Hotwork Ag

- Accuramech

- Interglass

- Heat Applications India Pvt. Limited

- WBT S.R.L.

The German company futronic GmbH, which is a subsidiary of the German Jetter AG, attained an exceptionally well reputation as a high-tech electronics engineering company world-wide. futronic holds the experience of 40 years developing, manufacturing and commissioning electronic controls for the hollow glass and tableware glass manufacturing industry, i.e. Electronic Timing Systems for various range of needs, Synchronous Drive Systems, hot end reject systems for stuck and down ware, a light barrier that handles flint glass, gateways to integrate components from other suppliers. Customer satisfaction and constantly improved quality are the focus of futronic´s activities.

We have been developing and manufacturing electronic control systems for more than four decades. Based on our experience in a variety of industries, we are in a position to offer a broad spectrum of proven solutions. As an ISO 9001-2008 certified company and technology partner for many key sectors of the economy, we enjoy a reputation among our international clients for quality, competence and dependability.

Refmon Monolithics Co. Ltd. was established at the beginning of 1997 by engineers having several decades of experience in the refractory industry investing both Hungarian and foreign capital. The company manufactures dried and fired refractories of low cement castables and ultra low cement castables, special insulating materials as well as refractory castables and masses for high temperature application. The state of the art production technology and the high quality materials make the wide range of the products possible in several fields. The refractory materials are produced in many different dimensions. In contrary to the traditional production process, the technologies applied by the company have low energy requirements and during the production minimal amount of waste and combustion products develop. The high quality insures a longer product life at the end-user, also increasing furnace/ladle availability whereby the specific cost of the refractories is reduced. Our major product groups: - Steel industry - Glass industry - Wear resistant products - Special products

UAS Messtechnik GmbH is an innovative company of international reputation in the field of instrumentation engineering. Due to our broad know-how and conclusive complete solutions for all kind of process industry, we are the ideal partner to increase the efficiency of your plant.

UAS provides custom-made automation solutions. Our process management systems ensure a communication based on a highly intelligent structure utilizing an open, freely definable architecture.

With our 50 highly qualified employees UAS is able to realize turnkey projects. Worldwide service and after sales support are part of our basic services.

Since the mid 1960's Hotwork has become most experienced and well known company for refractory drying and heating up on all kind of furnaces in the world. Thanks to our clients we can look back to 10.000+ projects and 400+ melting system around the world.

Over the years Hotwork has expanded to offer specialized services ranging from simple dry out using up to 4 burners in steel ladles or incineration furnaces to complex projects such as float furnace comissioning, alumina calciners, cat crackers (FCCU), coke ovens, circulating fluid bed boilers (CFB) as well as highly efficient complete combustion and melting technology for the glass and aluminum industry.

Hotwork maintains 250+ portable combustion equipment located in our hubs worldwide. Our 60+ highly skilled and experienced engineers are happy to be at your service.

Accuramech Industrial Engineering specializes in high precision spare parts, wear parts, assemblies and mechanisms for glass bottle forming machines.

Being a part of Verallia, Accuramech Industrial Engineering has been working since 1997 as an international supplier for IS machine spare parts.

Our location in Pune, the engineering hub of India for mechanical parts, presents us with an opportunity to develop a solid local network of over 45 machining suppliers. Our partner’s network is the result of 15 years of deep selection and close cooperation with Indian industrial actors. From sand to lost wax casting, conventional turning to 5 axis milling, this large number of local partnerships allows us to adapt to any requirement.

We offer spare parts, assemblies and mechanisms for IS machines used in glass bottle production.

Interglass makes innovative glass-forming lubricants that unleash the efficiency potential of leading glassmakers worldwide. In 1992, we founded Interglass with the goal of providing more glass-forming lubrication alternatives to glassmakers in Mexico. Thirty years later, we've become an inspiring partner for leading glassmakers in over 40 countries.

Products:

Swabbing compounds

Automated systems (IS Machine) lubricants

Synthetic lubricants

Mineral lubricants

Coatings and oils for silent chains

Shear blade lubricants

Cooling lubricants

Delivery equipment lubricants

The Professional Approach to Furnace Heat-up, Refractory Dry-out and Heat Treatment Services

With over 3 decades of experience in this field, Heat Applications India Pvt. Limited (HAL) is trusted across industries, around the world. This is possible through our highly trained and experienced team of over 70 Expert Personnel, who provide professional solutions to a global clientele, from industries operating high temperature plants and installations.

Our cutting edge, specially designed and portable High Velocity Burners alongside an array of associated equipment, provide precisely controlled heat, with a high degree of uniformity for all Refractory Dry-out, Pre-heating and Post Weld Heat Treatment requirements.

With more than 250 sets of equipment in our inventory in both India and overseas, HAL is able to provide highly personalised solutions across the globe.

WBT’s conveyor belts for hollow glass are essential for various high-temperature processes, including annealing furnaces, decoration furnaces, tempering furnaces, and accumulation tables. These metal mesh belts provide outstanding mechanical and heat resistance, ensuring reliability at every stage of production. They can be manufactured with round, flat, or semi-round wire, and our technical team designs custom mesh solutions based on specific client requirements.

WBT: Italian Excellence in Hollow Glass, the innovative solution for your conveyor belts WBT brings with it the experience and passion of a team that has been operating in the hollow glass sector for over 40 years. With a solid know-how and a deep understanding of production processes, WBT offers innovative and customized solutions to meet the needs of its customers. WBT operates internationally and its ability to adapt to different markets allows it to meet the needs of customers worldwide. WBT specializes in the production of high-quality metal mesh conveyor belts, silent chains, and cutting blades for the hollow glass industry. Our experience and passion for innovation allow us to offer customized and cutting-edge solutions to meet the most diverse needs. Our products are characterized by: * Durability and resistance: Our conveyor belts are made of high-quality materials and are designed to withstand the most demanding conditions. * Energy efficiency: Our products are optimized to reduce energy consumption and increase production efficiency. * Customization: We are able to offer customized solutions to meet the specific needs of our customers. Beyond the worldwide recognized quality of our products, we offer a personalized technical consultancy service to find the perfect solution for your specific needs. WBT is more than just a supplier: we are your trusted partner in the hollow glass industry. Choose WBT and join the ranks of the most innovative companies in the hollow glass sector.

WBT: Italian Excellence in Hollow Glass, the innovative solution for your conveyor belts WBT brings with it the experience and passion of a team that has been operating in the hollow glass sector for over 40 years. With a solid know-how and a deep understanding of production processes, WBT offers innovative and customized solutions to meet the needs of its customers. WBT operates internationally and its ability to adapt to different markets allows it to meet the needs of customers worldwide. WBT specializes in the production of high-quality metal mesh conveyor belts, silent chains, and cutting blades for the hollow glass industry. Our experience and passion for innovation allow us to offer customized and cutting-edge solutions to meet the most diverse needs. Our products are characterized by: * Durability and resistance: Our conveyor belts are made of high-quality materials and are designed to withstand the most demanding conditions. * Energy efficiency: Our products are optimized to reduce energy consumption and increase production efficiency. * Customization: We are able to offer customized solutions to meet the specific needs of our customers. Beyond the worldwide recognized quality of our products, we offer a personalized technical consultancy service to find the perfect solution for your specific needs. WBT is more than just a supplier: we are your trusted partner in the hollow glass industry. Choose WBT and join the ranks of the most innovative companies in the hollow glass sector.

About us

Providing Engineering Consulting Services & Products For Different Industries.

Alzar FZE was established in 1997 with one goal, to be able to gather the best solutions providers in the industries it serves. With this in mind, and having more than three decades of industrial experience prior to the establishment of Alzar FZE, we started a journey of selecting world-class partners in the Ceramics, Glass, Agriculture and Leather industries through a rigorous selection process and through extensive market research.

As your partner we consider to be part of your business, ensuring to add value directly to your bottom-line. We offer services and products to a diverse set of Industries, & deliver excellence through strong partnership with our world-class Principals.

Our technical expertise gained by years of experience combined with our committed and well educated Engineers will ensure that your company receives not only quality products, but also quality advice. We have built our reputation with long-term relationships in mind. Our existence depends on the prosperity of the companies we deal with, and we strive to help them grow rapidly and steadily.

As your partner we consider to be part of your business, ensuring to add value directly to your bottom-line. We offer services and products to a diverse set of Industries, & deliver excellence through strong partnership with our world-class Principals.

Our technical expertise gained by years of experience combined with our committed and well educated Engineers will ensure that your company receives not only quality products, but also quality advice. We have built our reputation with long-term relationships in mind. Our existence depends on the prosperity of the companies we deal with, and we strive to help them grow rapidly and steadily.

Have any questions?

info@alzarfze.com

Call us

+971 4 8814928-9

Fax

+971 4 8873928